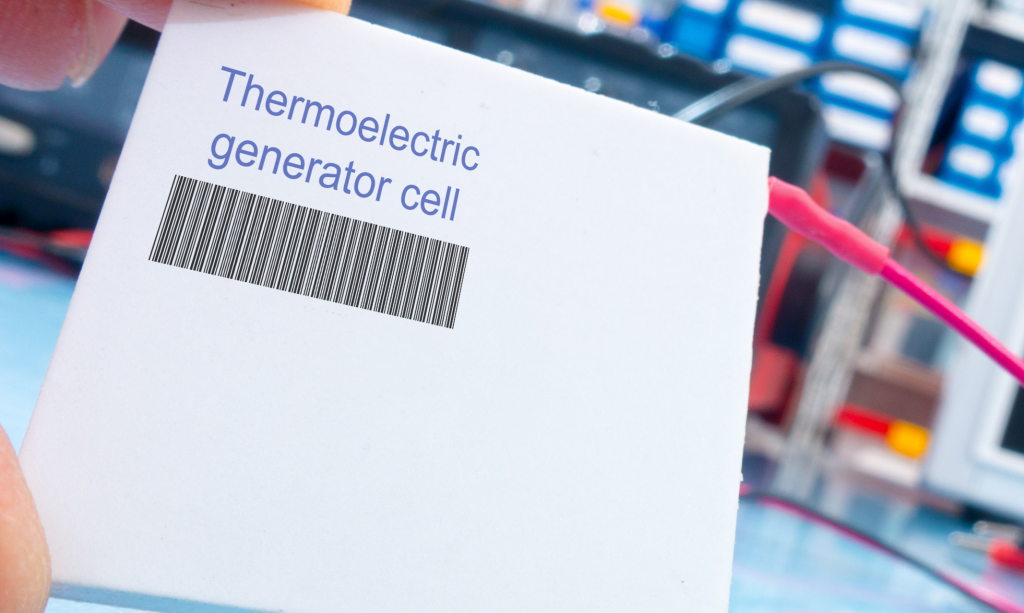

In the current times, where climate action is high on the agenda in politics and the demand for energy continues to grow, we ought to look for a variety of solutions that can generate cleaner energy and reduce waste. One technology worth examining in this context is ‘Peltier materials’ also known as thermoelectrics which can convert heat directly into electricity. Some improvements in this technology have been made in recent years thanks to nanotechnology which has resulted in new products and bigger economic incentives for uses in thermoelectric power generation.

Content:

- The basics

- The technical

- Applications

- Applications in nanotechnology

- Outlook

The basics

For a thermoelectric to create electricity, it requires a temperature difference. One side must be hotter than the other one or else it will stop working. A good material must therefore be good at conducting electricity but bad at conducting heat. For most materials, this is not the case which makes it hard to discover good thermoelectrics. Nanotechnology has helped a lot in coming up with new materials that have proven to be more efficient and are now used in commercial products.

The technical

The thermoelectric effect[i] is what allows for generation of electricity. When there is a temperature difference, more electrons from the hot side move to the cold side than the opposite which creates a Voltage difference and allows for energy harvesting.

To compare different thermoelectrics, the ZT value is used which is a combination of the Seebeck coefficient, electrical resistivity, thermal conductivity, and absolute temperature and gives an idea of the efficiency of the material to convert heat to electricity.

A recently discovered material showed a ZT value at 1.1 close to room temperature and an efficiency of 11 % conversion[ii]. This might not sound like a lot but can actually be used to power a lot of small devices. The best ZT value and the world record reported in 2019 from Vienna university was between 5-6[iii]. It uses a thin layer of iron, vanadium, tungsten, and aluminum applied to a silicon crystal.

It is a good number to be aware of but can sometimes be a bit misleading as scientists sometimes discover materials with high ZT values but where the scalability or reliability of the material becomes problematic. It is also important to look at which temperature range the product needs to be used at. A good ZT value is not worth a lot if it only works at a very narrow temperature range. The context is therefore important to be aware of.

Applications

Most applications of Peltier materials work the other way around where electricity is used to create a temperature difference for example to precisely control the temperature in a wine refrigerator. However, this post is focusing on the ability to generate electricity.

An easily relatable product using thermoelectrics is the Powerwatch 2 by Matrix Industries. It is a smartwatch that you, in principle, never have to charge and is powered by your own body heat and a small panel of solar cells. Their thermoelectric is based on a nanomaterial.

The biggest applications for generating electricity are where there is high energy waste in the form of heat. One example of this is in oil drillings that use ‘fracking’ where excess gas is often simply burned or ‘flared’ to reduce the risk of explosions when drilling due to large pressure building up. The burned gas is a waste product, which could instead be utilized by converting it to useful energy by having thermoelectric components installed. This has been attempted by the company Alphabet energy, which installed thermoelectric power generation at oil drillings around the US [iv]. Unfortunately, the company has since then gone out of business[v]. During operation, they were working on commercializing a thermoelectric material with silicon nanowires in it but meanwhile used a naturally occurring thermoelectric in their product for oil drillings.

There are other examples of industrial processes where there is high heat waste such as in steel mills and aluminum manufacturing. In long term, having small thermoelectrics in cars is something that would greatly reduce heat waste[vi]. So far it is not commercially available but has been demonstrated to be feasible and greatly researched for instance by the company Gentherm Incorporated[vii].

The application possibilities are endless, just think about situations where heat is a waste product. With continuous improvements in efficiency, more and more of these applications become economically viable.

Applications in Nano technology

An interesting field where thermoelectrics could perhaps fill in a gap is within nano- and micro-sensors. These, small sensing devices connected to the Internet of Things (IoT), are on the rise in fields such as medicine and diagnostics, agriculture, and production industries but often find the challenge of missing a source of energy other than using batteries. In some cases, thermoelectrics could be this source, thus making the sensors self-reliant and prolonging their lifetime.

This same challenge applies to the idea of nanorobotics and other nanoscale devices in remote locations that need to be self-sufficient as well. Thermoelectric power generation is, however, not the only solution. Other sources of energy could be solar or vibrations, but these are not always possible to use.

Outlook

As a technology on the rise, there’s still some way to go before thermoelectrics become mainstream. One of the biggest barriers for them to become used more is that there is no streamlined application process for each scenario. It requires some innovative thinking to find the proper way of installing it in already complex processes with heat waste, so even if it is profitable, it takes some time to get it to market.

Another barrier, however, is still their efficiency in power conversion. If thermoelectrics become more effective at harvesting electricity, the incentive to introduce them in different settings ultimately becomes larger. Lastly, a general lack of knowledge about the potential of thermoelectric power generation is an inhibitor for its use since production industries may not realize that there is a way for them to capture wasted heat and thereby reduce their energy consumption.

Nanotechnology has already played a big role in improving efficiency in thermoelectrics and will probably continue to do so as new materials are discovered within this space. It is nevertheless a combination of different factors that are needed before they become more widely used. According to ReseachandMarkets[viii], the global thermoelectric generators market is expected to grow from USD 460 Million in 2019 to USD 741 Million by 2025 with an average annual growth rate of 8.3 %. Some of the biggest players within this field are Gentherm, Inc. (US), II-VI Marlow, Inc. (US), and Ferrotec Corporation (Japan).

If you’d like to learn more about nanotechnologies, please subscribe to our newsletter and stay tuned for upcoming posts.

References:

[i] https://www.sciencedirect.com/topics/chemistry/thermoelectric-effect

[ii] https://pubs.rsc.org/en/content/articlelanding/2020/ta/c9ta12954e#!divAbstract

[iii] https://www.tuwien.at/en/tu-wien/news/news-articles/news/new-material-breaks-world-record-turning-heat-into-electricity/

[iv] http://www.fillerlab.com/nanovation/archive?offset=1506561253634

[v] https://www.businessinsider.com/most-valuable-us-startups-failed-went-out-of-business-2018-11?r=UK#16-ezhome-subscription-based-lawn-care-services-10

[vi] https://www.sciencedirect.com/science/article/abs/pii/S0196890419306429

[vii] https://www.gentherm.com/

[viii] https://www.researchandmarkets.com/reports/4848864/thermoelectric-generators-market-by-application?utm_source=GNDIY&utm_medium=PressRelease&utm_code=63v8nk&utm_campaign=1309474+-+Global+%24741M+Thermoelectric+Generators+Market+2019-2025+%7c+Forecast+by+Application%2c+Wattage%2c+Temperature%2c+Material%2c+Vertical%2c+Component%2c+and+Region&utm_exec=joca220prd