How do we know that we build nanostructures properly? The typical structures that make up the computer or similar smart device you’re reading this on contain billions of separate nanostructures, controlling the sizes of these has been a major challenge in the electronic industry since the conception of the first integrated circuit.

When fabricating these structures, many steps can go wrong. ‘Are the edges of the device properly rounded?’, and ‘is the necessary layer of my contact metal deposited on the wafer substrate?’ could be questions that need to be answered. However, to answer these questions, we must be able to see something that is the size of around one twenty thousandths the width of a human hair.

Here one might consider the use of a simple loop, perhaps one laying around from childhood and trying to see these nanostructures on one’s own, however a glass loop, and even dedicated optical glass microscopes cannot obtain the magnification necessary to visualize these incredibly small structures.

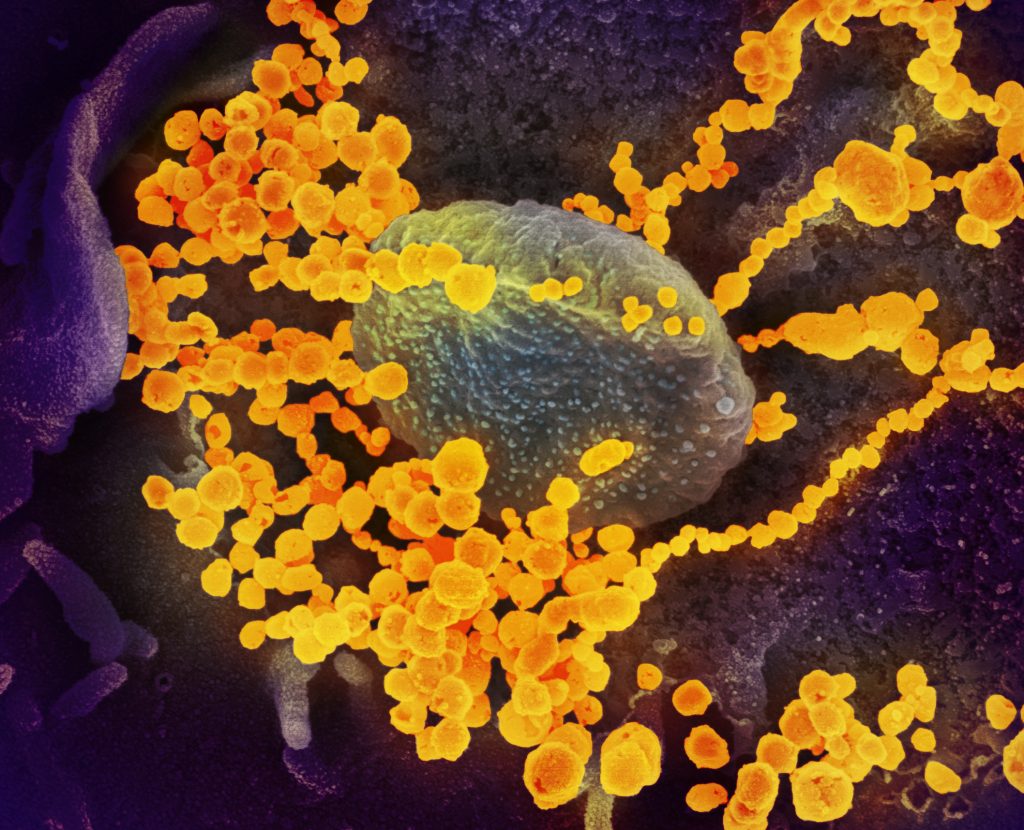

When using optical microscopes, technology hit a wall in trying to visualize small items, due to the inherent wavelength of the light that is used. Researchers then turned to the use of electrons, due to the possible wavelength of electrons being much smaller than ordinary light waves. This led to the field of electron microscopy, wherein many different types of microscopes have been developed, most of them able to reach a resolution on an atomic scale.

A common factor in all of these electron microscopes is the acceleration of electrons using high tension, where the electrons move extremely fast and directing them towards a sample with a certain structure. Due to different physical interactions with the sample and electrons, different ways of analyzing and visualizing the sample comes.

Modern devices require modern visualization, and in the time of single digit nanometer structures, modern visualization almost inherently requires the use of electron microscopes. This however proves difficult, since such a dedicated machine has proven to be very expensive, both in hardware, software, training sessions and even maintenance. This is however the price that is paid for atomic scale resolution and the important data an electron microscope can yield.

If you’d like to learn more about nanotechnology, please subscribe to our newsletter and stay tuned for upcoming posts.